Offered here is a state of the art, fully automatic Discharge and Processing system for metal chips. This ad is aimed at Companies

active in the metalworking business, and which are currenty handling their metal chips manually.

The chips ( swarf ) are formed as a by-product when milling, drilling or turning metal products. The chips will have to be carried

off in any case, after which they are usually traded for recycling.

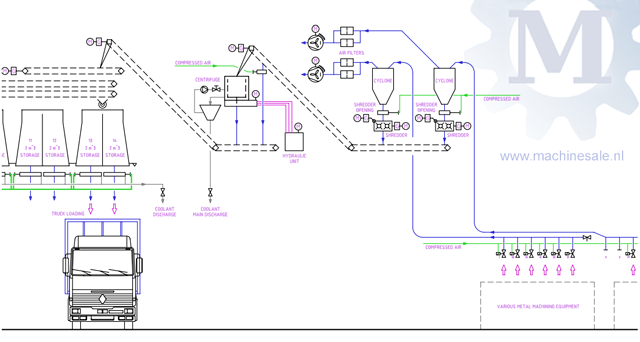

The system offered here includes all the components to automate the collection and improve the condition of the chips: Suction

nozzles, pneumatic transport, two shredders and an automatic de-oiling centrifuge. The de-oiled chips are stored in several seperate

storage compartments. The compartments are resting on two frames with a loadcell weighing system. Each compartment has a pneumatic

slide at the bottom, which can be opened to load a truck from the top.

This ad is for a new, high quality metal chip processing system. Using this system will ensure a reduction in labor costs, whilst reclaiming expensive cutting oils. It has been in operation for just one year (the original owner went bankrupt).

| Specifications: |

| Year of manufacture |

2011 |

| Storage bunkers |

14 pcs |

| Total Storage capacity |

28 cubic meter |

| De-oiling Centrifuge Specifications: |

| Brand + Type |

CEPA - KSE 400A |

| Chips Capacity |

850 liters/hour |

| Revolution |

1500 rpm |

|

This system consists of:

- 17 Suction interfaces

- 2 Suction blowers

- 2 Chip Shredders

- Automatic de-oiling centrifuge

- 14 Storage compartments on loadcells

- 5 chain conveyors

- Electrical control cabinet

|